Throughout history, we have always sought to achieve thermal balance. Our ancestors, for example, built stone houses to take advantage of their insulating properties, creating comfortable environments in winter and cool ones in summer. From these practices, concepts emerged that influenced the energy demand standards of the last century, aimed at maintaining pleasant temperatures.

The concept of heat recovery units is based on this same idea: harnessing the thermal properties, in this case of air flows, to maintain suitable temperatures without wasting energy.

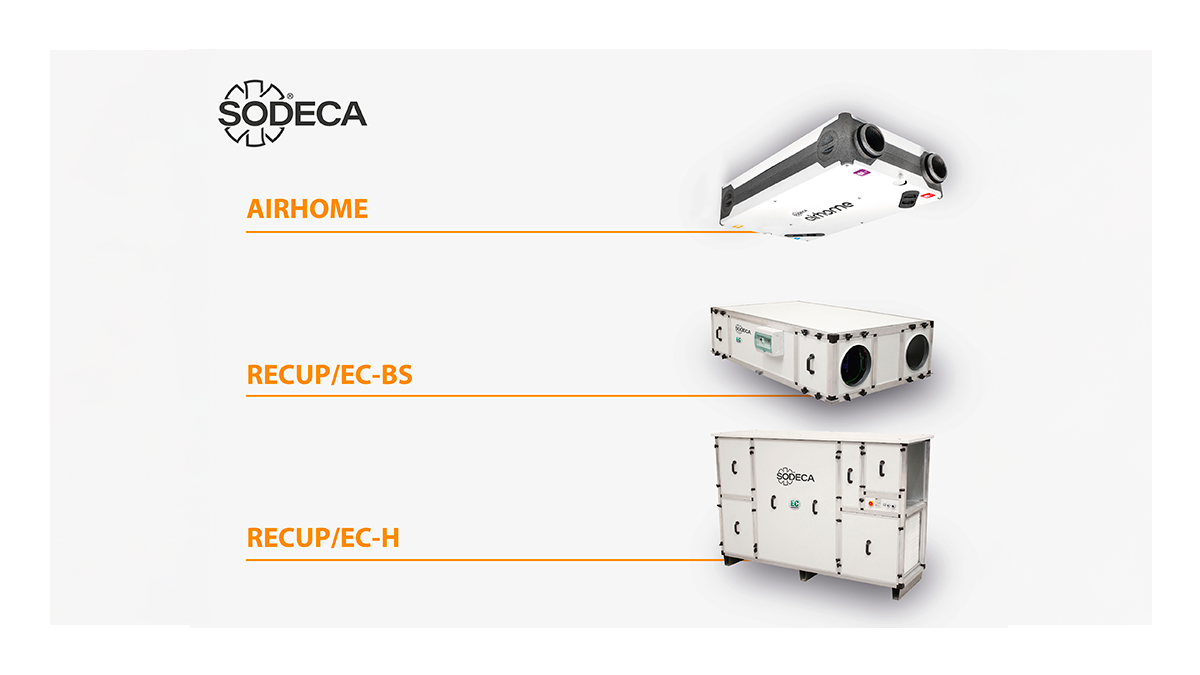

Heat recovery units are ventilation systems that not only allow for air renewal in buildings, but also temper it in the process. This contributes to energy savings because it reduces reliance on heating and cooling systems. Therefore, heat recovery units are effective in achieving both energy efficiency and optimal indoor air quality. SODECA offers models adapted to different needs, such as the AIRHOME, specifically designed for homes, and more robust models for larger tertiary buildings with higher foot traffic, such as the RECUP/EC-BS and RECUP/EC-H.

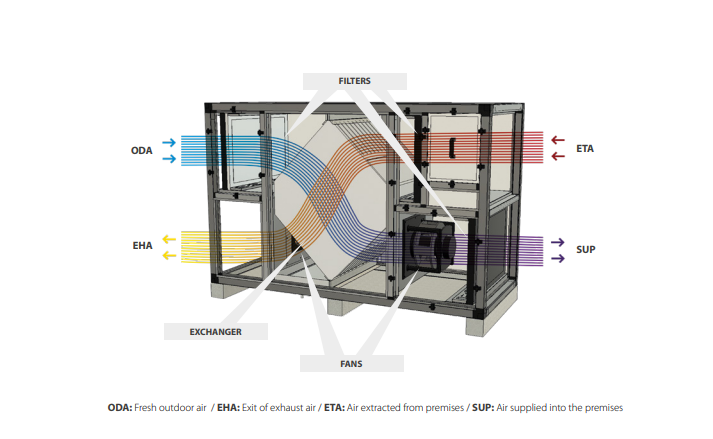

The operation of these systems is based on heat exchange. That is, they utilise the temperature—and sometimes also the humidity—of the stale air being expelled to transfer it to the fresh air being brought in from outside. This process of harnessing existing heat and humidity during ventilation is called energy exchange.

The key component to carry out this procedure is called the heat exchanger. It is located inside the unit and can be made from different materials that facilitate this energy exchange.

Heat exchangers are generally classified into two types: sensible exchangers, which are mainly made of aluminium (which performs very well in relation to temperature), and can store energy, both cold and heat, in the plates. However, this type of exchanger does not recover the humidity of the air.

In environments where the goal is to utilise the differences in humidity between the interior and exterior to maintain a comfortable environment, enthalpic exchangers are preferred. These are usually made from cellulose materials, which can store both energy and moisture in their plates or folds.

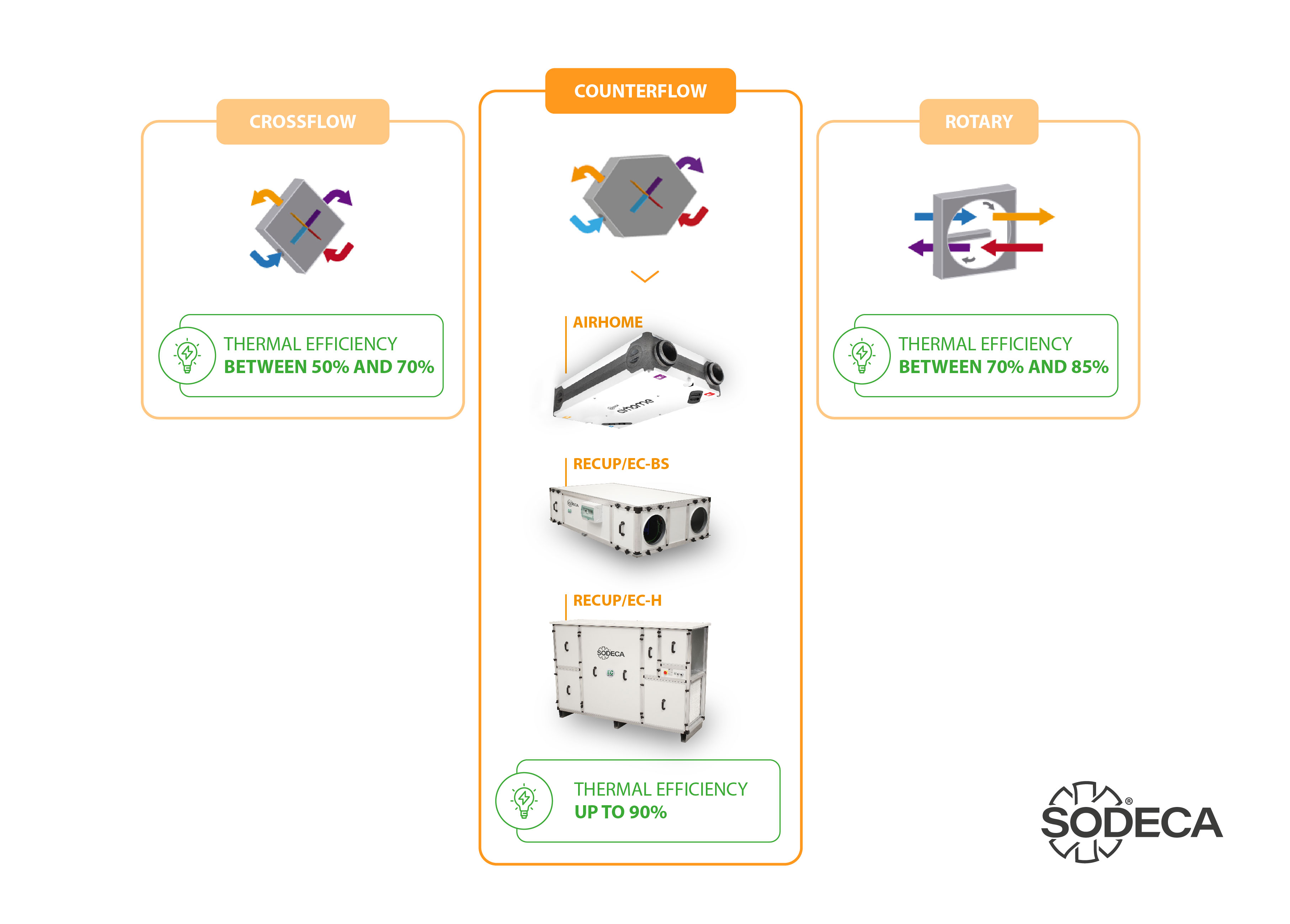

Along with the type of exchange—sensible or enthalpic—there is also the shape of the heat exchanger, that is, how the two air flows circulate through the component. There are three types of heat exchangers: crossflow exchangers, where the supply and exhaust flows cross at 90 degrees, without leaks and at a lower cost; counterflow exchangers, which allow for a higher transfer of heat and humidity, reaching an efficiency of up to 90%; and rotary exchangers, based on a wheel with micro-channels that exchange heat through its rotation, suitable for large airflows, though they can have leaks between circuits. SODECA offers various models with counterflow plates, which are the most thermally efficient, both for homes, such as the AIRHOME, and for large tertiary buildings.

There are occasions when it might be more advantageous not to perform any temperature exchange. For these cases, SODECA’s heat recovery units also include a thermal by-pass.

The by-pass is a device that diverts the airflow and prevents it from passing through the heat exchanger and the thermal exchange unit. This component, for example, allows a space to be cooled quickly when the indoor temperature is too high, and the outdoor temperature is more suitable for the need.