The smoke control solutions based on overpressure rely on pressurising evacuation routes, such as stairwells, vestibules, hallways, or elevator shafts, through the injection of air. This method ensures that these routes remain smoke-free during emergencies by creating a flow of air and a pressure barrier through overpressure.

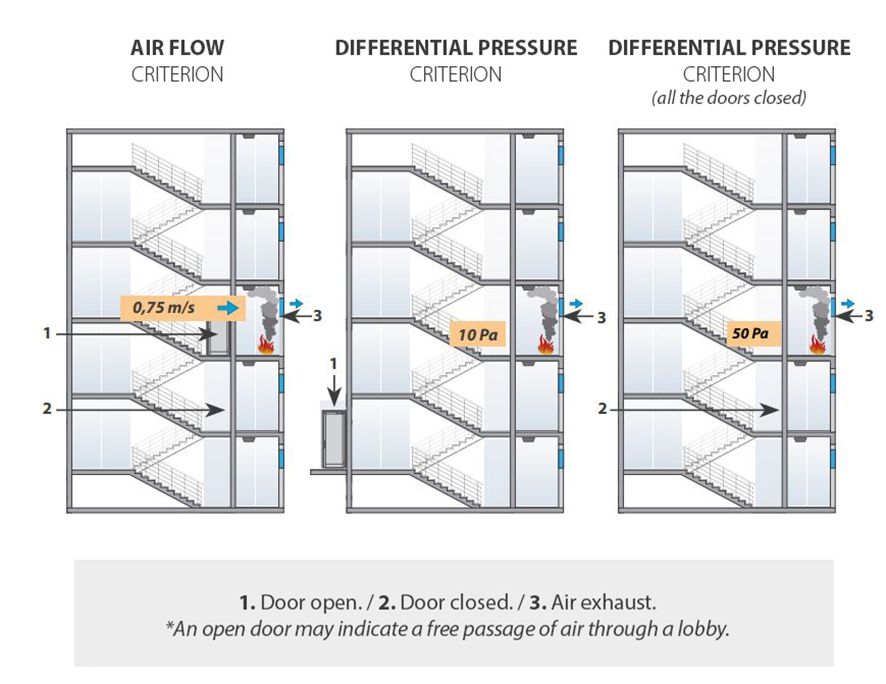

To achieve this, the system considers different situations involving open or closed doors that might occur during an emergency, due to the movement of evacuated people and firefighters. When all doors are closed, the system ensures a higher level of overpressure in the evacuation routes compared to the area affected by the fire. In this way, smoke is prevented from entering the staircase, as air flows from the higher-pressure protected area into the lower-pressure fire-affected area.

However, it is crucial that the overpressure does not become so high that it makes opening the doors impossible, ensuring a balance between the minimum pressure required to prevent smoke from entering and the maximum pressure that allows doors to be opened. Typically, in the case of closed doors, the proper pressure in the protected stairwell is 50 pascals.

If a door between the protected and non-protected areas is opened during evacuation, the pressurisation system must adapt to this new situation. A well-designed differential pressure system should respond quickly to the door's opening to maintain sufficient overpressure in the protected space and ensure that air passes through the open doors at a certain velocity in the affected floor. With one or more doors open, the potential for smoke penetration increases, and pressure tends to equalize between the pressurised and non-pressurised zones. To counteract this, and prevent smoke from entering the protected staircase, the system significantly increases the air flow in the evacuation routes.

By increasing the air flow, the system ensures that clean air continues to be pushed outward through the open doors, maintaining a higher pressure inside the staircase, which is essential to prevent smoke entry and enable a safe evacuation. In this regard, SODECA’s equipment can provide 90% of the required air flow in less than 3 seconds.

System Sizing

However, not all pressurisation systems function in the same way; they must be adapted to the environment in which they are used. According to European design standards, the appropriate system must be chosen based on the building’s usage and the planned evacuation procedures in case of fire. These factors determine the necessary air flow that the overpressure system must deliver and help in selecting the pressurization equipment consciously.

For this reason, SODECA manufactures pressurisation solutions tailored to different types of buildings to meet their specific needs. These solutions are divided into three levels: Full Range, Advanced, and Basic, each designed to meet different pressurisation requirements based on the building type, its use, and evacuation conditions.

Fortunately, nowadays it is easy to choose the right equipment, as tools exist to simplify these calculations and assist in designing projects that comply with the current standards. QuickFan, SODECA’s ventilation software, considers the essential factors for calculating the required pressurisation for different type of buildings in an intuitive manner, taking into account each of the hypotheses posed by the standard. Additionally, QuickFan allows you to select the appropriate pressurisation equipment immediately after the automatic calculation.

You can easily download QuickFan software from SODECA’s website.

In conclusion, the pressurisation of stairwells and other evacuation routes enhances the safety of people in emergency situations. Keeping these areas smoke-free, enabling a quick and safe evacuation, and providing access for firefighters are key factors that, combined with fire detection and alarm communication systems, and evacuation plans, can save lives.

For more information, contact our technical advisory service for personalized assistance.