Smoke exhaust systems

Solutions for smoke extraction in the event of fire

When a fire breaks out in a building, whether residential or industrial, it is necessary to extract smoke from the fire area to evacuate people and possible victims, protect the building structure and facilitate access for fire-fighting equipment. All SODECA smoke extractors and ventilation solutions meet the most rigorous standards and are certified by independent laboratories.

Applications

Smoke extraction in the event of a fire is essential for ensuring the safe and efficient evacuation of buildings, while reducing the propagation of fire and minimising the material damages and human injury.

Car parks

In car parks, ventilation can be natural or mechanical. In the latter case, Jet Fans must be installed to properly move the air and maintain the required conditions of safety and comfort under normal conditions, as well as in the event of a fire.

MECHANICAL through ducts

MECHANICAL through ducts

MECHANICAL assisted by impulse ventilation

MECHANICAL assisted by impulse ventilation

NATURAL assisted by impulse ventilation

NATURAL assisted by impulse ventilation

Industrial buildings

These ventilation systems extract the hot gases generated at the start of a fire and create smoke-free zones underneath the floating smoke layers, thereby improving evacuation conditions and facilitating firefighting. They also prevent secondary fires and control the temperature of the smoke to prevent a building from collapsing.

Smoke exhaust in SINGLE-STORY BUILDINGS

Smoke exhaust in SINGLE-STORY BUILDINGS

Smoke exhaust in MULTI-STORY BUILDINGS

Smoke exhaust in MULTI-STORY BUILDINGS

Cold storage rooms

The implementation of a smoke control system in the event of a fire in cold storage rooms involves unique differences with respect to traditionally installed smoke control systems in industrial buildings. The presence of a double roof (composed of the cold storage room's ceiling and the roof of the building) complicates the process of extracting the smoke generated by a fire inside the cold storage room towards the exterior. The equipment installed on the casing of the cold storage room requires thermal insulation features in order to prevent high energy losses.

Direct from the cold storage room

Direct from the cold storage room

Exhaust by plenum

Exhaust by plenum

Conducted from the cold storage room

Conducted from the cold storage room

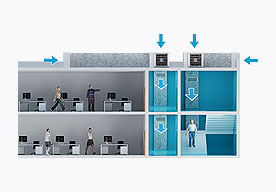

Evacuation routes

Pressurisation control systems protect evacuation routes in the event of fire by preventing the entry of smoke through air overpressure. If the doors are opened or in the event of air leaks, the system reacts by increasing the flow rate. This guarantees that the escape routes are always free of smoke in an emergency situation.

Intake of outside air

Intake of outside air

Joint pressurisation of lobbies

Joint pressurisation of lobbies

Pressurisation air exhaust

Pressurisation air exhaust

Individual pressurisation of lobbies

Individual pressurisation of lobbies

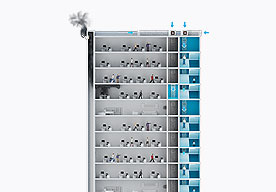

High-rise buildings

High-rise buildings

Tunnels

The reliability of the tunnel ventilation system is essential to ensure the safety of users over time. Tunnel ventilation can be natural or forced. In the last case, fans should be installed to generate adequate air movement to maintain safe conditions both in comfort mode and in case of emergency.

Longitudinal ventilation

Longitudinal ventilation

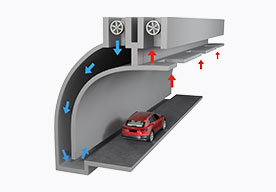

Transverse ventilation

Transverse ventilation

Semi-transverse ventilation

Semi-transverse ventilation

Our projects department

For the correct design of a smoke control system, SODECA has a Projects Department formed by technicians who specialise in offering personalised advice from the initial phase of a project by providing a complete technical study that includes:

· Size calculations

· Equipment location drawings

· The operating logic of the system

· The specifications of all the equipment that form a part of the system

Including the smoke exhaust fans, outside air supply fans, smoke control dampers and system control panels.